Thanks for downloading catalogue.

The cold rolled coil is essentially hot rolled steel that has undergone additional processing. Once hot rolled steel has cooled, it is then passed through the rollers at room temperature to achieve more exact dimensions and better surface qualities.

With better surface properties than hot rolled steel coils, it is often used for more technically precise applications or where aesthetics are important. However, due to the additional processing cold finished products come at a higher price.

In terms of physical characteristics, cold rolled steel coils are typically harder and stronger than hot rolled steel coils. As the metal is shaped at the lower temperature resistance against deformation, resistance against tension breaking and the steel’s hardness are all raised due to hardening.

The “cold rolled” is often used to describe a range of finishing processes, though technically, “cold rolled” applies only to sheets that undergo compression between rollers. However, forms like tubes or bars are “drawn” and not rolled. Hot rolled tubes and bars once cooled, are processed into what are called “cold finished” tubes and bars. Other cold finishing processes include polishing, grinding, and turning. Each of which is used to modify existing hot rolled stock into more refined products.

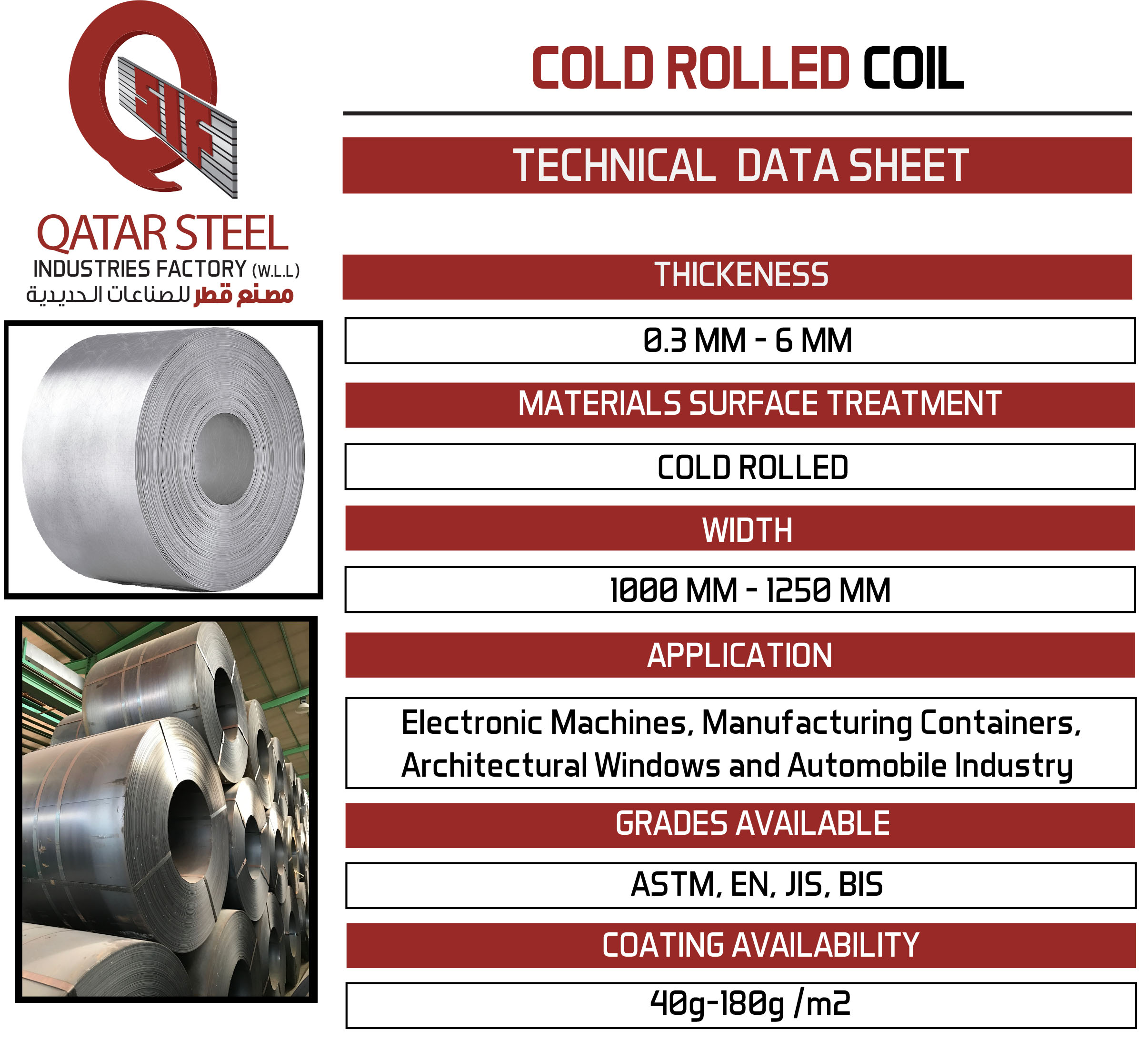

At Qatar Steel Industries Factory cold rolled steel coils can often be identified by the following characteristics:

- Tubes have better concentric uniformity and straightness.

- Smooth surfaces that is often oily to the touch.

- Better more finished surfaces with closer tolerances.

- Bars are of proper dimensions and have well-defined edges and corners.

- Dimensional thickness ranging from 0.3 to 6mm and width ranging from 1000 to 1250 mm.

- Protective coating grade ranging from 40g to 180g.