The House of Tees

The Tees form the main structural foundations for ceilings and are ranked in their quality based on their ability to manage load and deflection. Technically, load is the weight of the structure which is split into live and dead loads. Live loads are the weight and stress the structure bears from occupants, environmental elements like sand, wind and earthquakes. Dead loads are the weight of the structure itself. Deflection is the balancing factor whereby the Tee manages lateral load by deflecting against it and while maintaining complete functionality.

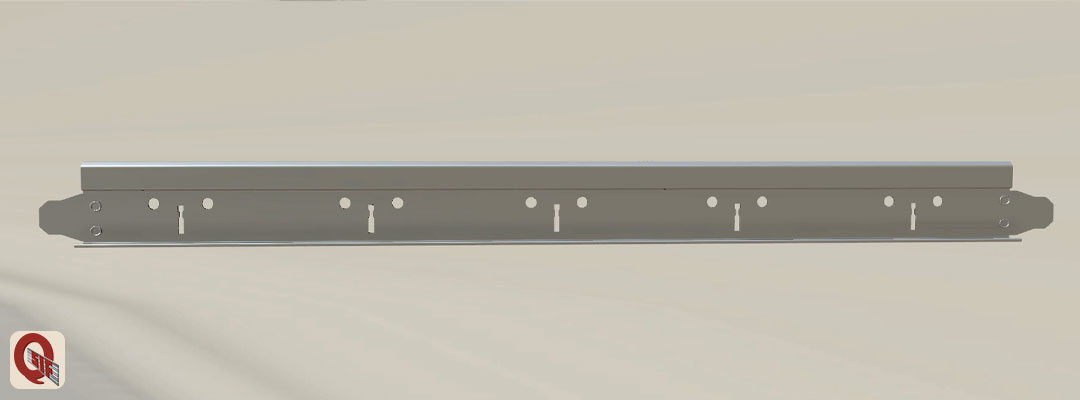

All Tees in Qatar Steel Industries Factory are manufactured from roll-formed galvanized steel, which is fully corrosion-free and rust-resistant. Three particular variants are produced using these techniques:

- Main Tees

- Cross Tees

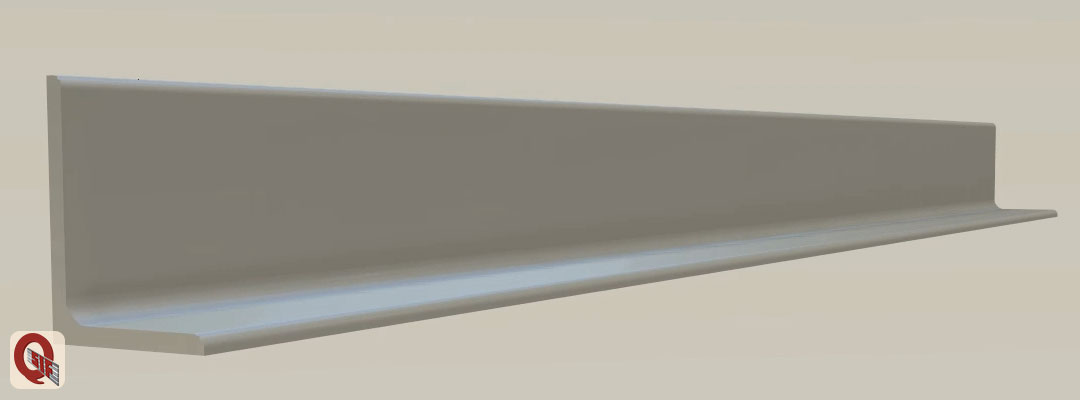

- Angle Tees

These Tees form the backbone of the ceiling structure and span across the room held up by joists using wire hangers. They are easy to assemble and fit snuggly at the joints thanks to their tool-less lock-in splices. This is mainly due to flush joints that eliminate gaps and ensure a snug fit at the joint. Furthermore, they are designed to be modular and practical making repairs, replacements and upgrades very easy.

Cross Tees are the supports that connect the Main Tees in a grid pattern to lock in the ceiling panels. Due to this, it is vital that both load and deflection factors are kept within ideal ranges as an imbalance in any can cause severe structural damage and even collapse. To select the surfacing material the deflection factor needs to be taken into account keeping in mind that these can vary based on the type of assembly used. Like the Main Tees, the Cross Tees are spliced in a way that no tools are required for fitting and are snug and tight when they latch on.

These are galvanized roll form steel moulded into an “L” shape that supports and finishes the ceiling around its perimeter. These are manufactured by bending steel in a single angle whereby they commonly appear and are finished at a 90-degree angle. These angle Tees can have both unequal and equal lengths for the legs of the “L” shape they form.

At installation, one needs to keep in mind that the minimum lateral load for the partitions is 240 Pa and for the exterior is 720 Pa to 2160 Pa or greater depending on the structural height and topography. Thus the right system must be in place that can manage the calculated load and deflection. Failure to do so could lead to unavoidable stress on the ceiling and damage to the fixtures.

For systems that are installed in drywall setups, it is important to limit deflection to L/240 and to never exceed L/120, where L is the length of the span. For veneer, the limit is L/360 and should not go beyond L/240. The larger the Angle the more load and stress it can bear.

One can find angles commonly used for Framing. They are also used for brackets, trim, reinforcements etc.